Due to the high light transmittance of transparent plastics, the surface quality of plastic products must be strictly required, and there should be no markings, pores, and whitening. Haze, black spots, discoloration, poor gloss and other defects, so in the entire injection molding process, we must pay great attention to the design of raw materials, equipment and even products and put forward strict or even special requirements. Secondly, since most of the transparent plastics have high melting point and poor fluidity, in order to ensure the surface quality of the product, it is often necessary to make fine adjustments to the process parameters such as high temperature, injection pressure, injection speed, etc., so that the plastic injection can not only fill the mold, but also not. Internal stress will cause product deformation and cracking.

Let's talk about the matters that should be paid attention to in terms of raw material preparation and injection molding process.

Preparation and drying of raw materials

Since any impurity contained in the plastic may affect the transparency of the product, and therefore storage and transportation. During the feeding process, attention must be paid to sealing to ensure that the raw materials are clean.

Cleaning of barrel, screw and accessories

In particular, the raw material contains moisture, which will cause the raw material to deteriorate after heating, so it must be dried, and a drying hopper must be used for feeding during injection molding. It should also be noted that in the drying process, the input air should preferably be filtered and dehumidified to ensure that the raw materials will not be polluted.

In order to prevent the contamination of raw materials and the existence of old materials or impurities in the depressions of the screw and accessories, especially the resin with poor thermal stability, the screw cleaning agent should be used to clean all parts before use and after shutdown, so that no impurities can be attached. When there is no screw cleaning agent, the screw can be cleaned with pe, ps and other resins.

When temporarily shutting down, in order to prevent the raw materials from staying at high temperature for a long time and causing degradation, the temperature of the dryer and the barrel should be lowered, such as the barrel temperature of pc, pmma, etc. should be lowered to below 160 °C. (Hopper temperature should drop below 100°C for pc)

Attention should be paid to the injection molding process:

In order to reduce internal stress and surface quality defects, the following aspects should be paid attention to in the injection molding process:

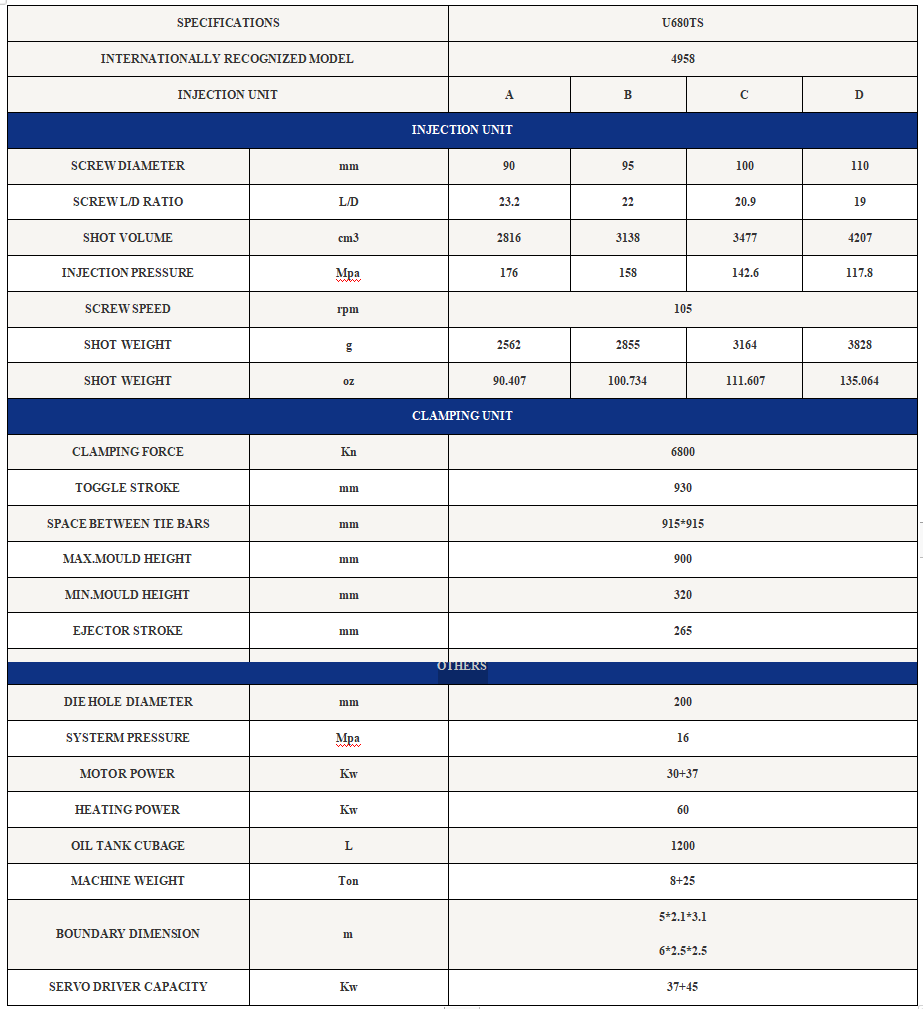

Special screw and injection molding machine with separate temperature control nozzle should be used.

The injection temperature should be higher than the injection humidity under the premise that the plastic resin does not decompose.

Injection pressure: generally high to overcome the defect of high melt viscosity, but too high pressure will cause internal stress to cause demolding difficulties and deformation;

Injection speed: In the case of satisfying mold filling, it should generally be low, and it is best to use slow, fast, and slow multi-stage injection.

Pressure holding time and molding cycle: In the case of satisfying the product filling and no dents and bubbles; it should be as short as possible to minimize the residence time of the melt in the barrel.

Screw speed and back pressure: under the premise of satisfying plasticizing quality, it should be as low as possible to prevent the possibility of degradation.

Mold temperature: The cooling quality of the product has a great impact on the quality, so the mold temperature must be able to accurately control the process. If possible, the mold temperature should be higher.